Maintaining the cleanliness of breast pump parts is of utmost importance for the health and well-being of both the breastfeeding mother and the baby. Breast milk is a rich medium for bacteria and other microorganisms to grow, and if pump parts are not cleaned properly, it can lead to contamination, which may cause infections in the mother or the baby. In this article, we will explore in detail the proper methods and steps for cleaning breast pump parts.

Why Cleanliness is Crucial

1. Protecting the Baby’s Health

The baby’s immune system is still developing, and any exposure to harmful bacteria or contaminants in breast milk can have serious consequences. Bacteria such as Staphylococcus aureus or Escherichia coli can cause infections like mastitis in the mother and gastroenteritis or other infections in the baby. Clean breast pump parts help to ensure that the breast milk remains pure and free from pathogens, reducing the risk of these health issues.

2. Ensuring the Mother’s Well-being

For the mother, using a clean breast pump helps prevent infections in the breast tissue. If bacteria build up on the pump parts and are reintroduced into the breast during pumping, it can lead to painful conditions. Additionally, a clean pumping environment and equipment can make the pumping process more comfortable and efficient.

Pre-cleaning Steps

1. Disassembling the Pump

The first step in cleaning breast pump parts is to disassemble the pump properly. Different breast pumps have various components, but commonly, parts like the breast shields, valves, tubing, and collection bottles need to be separated. It is important to follow the manufacturer’s instructions for disassembly as some pumps may have specific mechanisms or parts that require careful handling. For example, some valves may be small and delicate and need to be removed without damage.

2. Rinsing Immediately After Use

As soon as possible after using the breast pump, it is advisable to rinse all the parts with warm water. This helps to remove the initial layer of breast milk, which can start to coagulate and become more difficult to clean if left for a long time. Rinsing also reduces the amount of residue that will need to be cleaned later, making the overall cleaning process more effective.

Washing with Soap and Water

1. Choosing the Right Soap

When washing breast pump parts, it is essential to use a mild, unscented soap. Harsh soaps or those with strong fragrances may leave a residue that can be harmful to the baby or affect the taste of the breast milk. Baby-safe dish soaps are a good option as they are formulated to be gentle. Avoid using antibacterial soaps regularly as they may disrupt the natural balance of bacteria and potentially lead to the development of resistant strains.

2. Scrubbing the Parts

Using a soft brush or a clean cloth, gently scrub all the parts of the breast pump. Pay special attention to areas where breast milk may accumulate, such as the crevices of the breast shields and the insides of the valves. The tubing should also be cleaned, either by running a soapy solution through it or using a tubing brush if available. For example, the breast shield should be scrubbed both on the inside and outside to remove any milk residue. Make sure to rinse all the parts thoroughly with warm water after scrubbing to remove all traces of soap.

Sanitizing the Parts

1. Boiling Method

One of the most common ways to sanitize breast pump parts is by boiling. Place the disassembled parts in a large pot of boiling water. Make sure that all the parts are fully submerged and boil for about 5 – 10 minutes. However, it is important to note that not all breast pump parts are suitable for boiling. Some plastic parts may warp or become damaged. Check the manufacturer’s instructions to determine if boiling is a recommended sanitization method for your specific pump parts. For example, silicone parts generally withstand boiling better than some types of plastic.

2. Steam Sanitizing

Many modern breast pumps come with a steam sanitizing option. This involves using a steam sanitizer, which heats water to produce steam that kills bacteria and other microorganisms. Place the clean, rinsed parts into the steam sanitizer according to the manufacturer’s instructions and run the cycle. Steam sanitizing is convenient and effective, and it is less likely to damage the pump parts compared to boiling. It also reaches all the nooks and crannies of the parts, ensuring thorough sanitization.

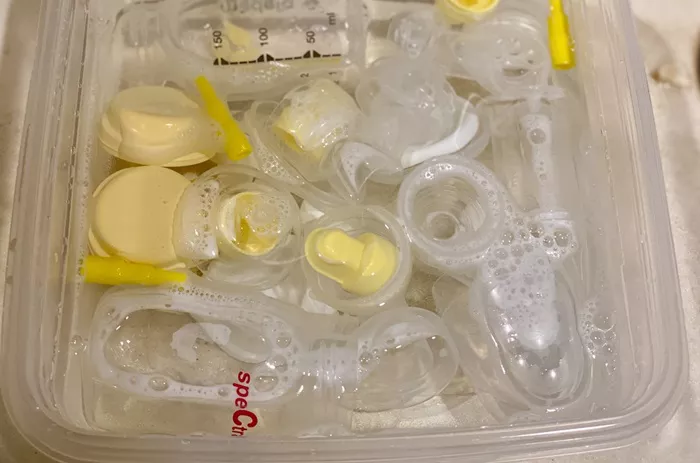

3. Using a Sanitizing Solution

Another option is to use a sanitizing solution specifically designed for breast pump parts. These solutions are usually available in liquid or tablet form. Dilute the solution according to the instructions and soak the parts in it for the recommended time, usually around 30 minutes. After soaking, rinse the parts thoroughly with clean water. This method is useful for those who may not have access to boiling water or a steam sanitizer.

Drying the Parts

1. Air Drying

After sanitizing, allow the breast pump parts to air dry. Place them on a clean, dry towel or a drying rack in a well-ventilated area. Avoid using a cloth to dry the parts as it may introduce lint or bacteria. Letting the parts air dry naturally helps to ensure that they are completely dry before the next use. This is important because any moisture left can promote the growth of bacteria. For example, the tubing should be hung up to allow any remaining water to drain out completely.

2. Using a Clean Towel (with Caution)

If you need to use a towel to speed up the drying process, make sure it is a clean, lint-free towel. Gently pat the parts dry rather than rubbing them. Rubbing can cause scratches or damage to the parts, especially those made of plastic or silicone. However, air drying is still the preferred method as it reduces the risk of contamination.

Frequency of Cleaning

1. After Each Use

It is recommended to clean breast pump parts after each use. This helps to prevent the build-up of breast milk residue, which can become a breeding ground for bacteria. Even if you are pumping multiple times in a short period, it is important to at least rinse the parts after each session and then do a more thorough cleaning at the end of the day.

2. Deep Cleaning

In addition to the regular after-use cleaning, a deep cleaning should be done at least once a week. This involves a more detailed inspection and cleaning of all the parts, including disassembling any parts that are not usually taken apart during normal cleaning. It also gives an opportunity to check for any signs of wear and tear or damage to the pump parts.

Storage of Cleaned Parts

1. Using a Clean Container

Once the breast pump parts are clean and dry, store them in a clean, covered container. A plastic storage box or a dedicated breast pump storage bag can be used. Make sure the container is clean and dry before storing the parts to prevent any recontamination.

2. Keeping in a Safe Place

Store the container in a clean, dry area away from sources of dirt, dust, and moisture. Avoid storing the parts in a damp bathroom or near a kitchen sink where they may be exposed to splashes or spills.

Conclusion

Properly cleaning breast pump parts is an essential aspect of breastfeeding. By following the steps of disassembling, rinsing, washing with mild soap, sanitizing, drying, and storing correctly, mothers can ensure the safety and quality of breast milk. Regular and thorough cleaning not only protects the baby from potential infections but also helps maintain the mother’s breast health and the efficiency of the breast pump. It is important to always refer to the manufacturer’s instructions for specific guidance on cleaning and maintaining the particular breast pump being used. With careful attention to cleanliness, breastfeeding can be a more comfortable and healthy experience for both mother and baby.

Related Topics: